Advanced Telescope Building Materials: Essential Insights

Category: Astrophotography

Discover the Best Materials for Advanced Telescope Building

Whether you're an avid amateur astronomer, a passionate space engineering hobbyist, or an astrophotography learner ready to build your own telescope, choosing the right materials is a critical step that can make or break your project. You’ve likely scoured beginner guides that only scratch the surface, or generic reviews that don’t address the nuances of optical performance, structural stability, and environmental resilience crucial for advanced telescope builds. This post is crafted precisely for you: someone who understands the basics, seeks to elevate their craft, and demands practical, in-depth information. We'll dive deep into advanced materials — from specialized composites and metal alloys to optical glasses and coatings — explaining their properties, benefits, and trade-offs. Whether you're designing for high precision astrophotography or a custom engineered large-aperture instrument, this comprehensive guide will save you time, prevent costly mistakes, and empower your build with confidence. Read on to uncover expert-recommended materials and build strategies that outperform common choices and fit your unique astronomical goals.

- Discover the Best Materials for Advanced Telescope Building

- Overview of Key Material Properties for Telescope Building: Rigidity, Thermal Stability, Weight, and Durability

- Advanced Optical Materials: Types of Glass and Crystals for Lenses and Mirrors

- Structural Frame Materials: Comparing Aluminum Alloys, Carbon Fiber Composites, and Titanium for Telescope Tubes and Mounts

- Mirror Substrates and Coatings: Enhancing Reflectivity and Reducing Aberrations

- Thermal Management in Materials: How Material Choices Affect Thermal Expansion, Distortion, and Image Clarity During Observations

- Material Innovations in Vibration Damping and Stability: Incorporating Viscoelastic Polymers and Honeycomb Structures for Vibration Reduction

- Protective and Environmental Considerations: Weather Resistance, Corrosion Protection, and Dust Control in Telescope Materials

- Material Selection for Portable vs. Fixed Telescopes: Trade-offs in Weight, Strength, and Cost

- Integration with Astrophotography Equipment: Materials Optimizing Compatibility with Cameras, Filters, and Adaptive Optics Systems

- Sourcing and Cost Considerations: Where to Find Advanced Telescope Materials and How to Balance Budget with Performance Needs

Overview of Key Material Properties for Telescope Building: Rigidity, Thermal Stability, Weight, and Durability

When selecting materials for advanced telescope construction, understanding the core physical properties that impact performance is essential. Four attributes stand out as fundamental criteria: rigidity, thermal stability, weight, and durability. Each of these properties influences how well your telescope will maintain optical alignment, resist environmental stresses, and deliver sharp, consistent images over time.

-

Rigidity

A telescope’s optical components require precise positioning to achieve optimal focus and image clarity. Materials with high rigidity minimize flex, bending, and vibrations caused by wind, handling, or mechanical drive systems. Excessive flex or movement leads to misalignment, deteriorating image quality—especially in large aperture and long focal length instruments. Materials such as carbon fiber composites and certain aluminum alloys excel by offering exceptional stiffness-to-weight ratios that maintain structural integrity without bulk. -

Thermal Stability

Thermal expansion and contraction due to temperature fluctuations can cause components to shift, distorting the optical path and ruining delicate calibrations. Choosing materials with a low coefficient of thermal expansion (CTE) is critical for preserving long-term focus and calibration. Fused silica glass, Zerodur, and Invar alloys are popular in precision optics and support structures because their thermal stability reduces distortion even across wide temperature ranges encountered during night observing. -

Weight

A lightweight design is particularly important for portable telescopes, mounts, and astrophotography rigs. Reducing mass minimizes strain on motors, eases transportation, and enhances mounting stability. Advanced materials like carbon fiber composites and titanium alloys provide significant weight savings compared to traditional steel while retaining strength and stiffness. Balancing weight and rigidity is a key design challenge that directly impacts usability and performance. -

Durability

Telescope components must withstand environmental exposure, frequent handling, and long-term wear. Resistance to corrosion, UV degradation, and mechanical abrasion ensures longevity and reduces maintenance. Protective coatings, anodizing, and material choices such as stainless steel or treated aluminum help maintain structural soundness and aesthetic quality over years of use. Durability also encompasses resistance to microcracking or fatigue, which could compromise optical alignment.

By prioritizing materials that optimize these four properties, advanced telescope builders can achieve superior optical performance, structural resilience, and lasting functionality. In the following sections, we will explore specific materials and composites that meet these stringent criteria, empowering you to make informed choices for your next high-performance telescope project.

Image courtesy of Cosmin ChiWu

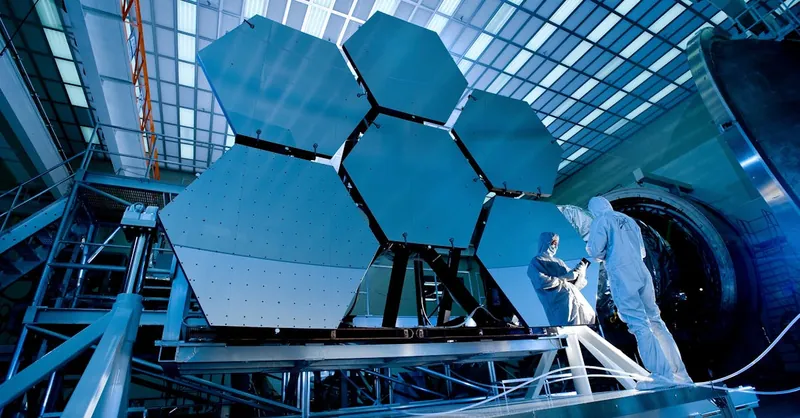

Advanced Optical Materials: Types of Glass and Crystals for Lenses and Mirrors

The heart of any high-performance telescope lies in its optical components—primarily the lenses and mirrors. Selecting the right type of glass or crystal material is crucial for achieving optimal light transmission, minimal aberrations, and long-term stability under varying environmental conditions. Among the vast array of optical materials available, some stand out due to their exceptional thermal properties, homogeneity, and ease of fabrication.

Fused Silica (Quartz Glass)

Fused silica is prized for its ultra-low thermal expansion, making it an ideal choice for telescope optics exposed to fluctuating temperatures. This synthetic amorphous form of silicon dioxide boasts excellent transmission across ultraviolet to near-infrared wavelengths. Its resistance to thermal shock and chemical inertness ensures durability and stable optical performance. Fused silica mirrors and lenses maintain focus and minimize distortion during night-to-day temperature shifts, critical for precision astrophotography and large research instruments. Moreover, its low birefringence enhances image quality by reducing polarization effects.

BK7 Optical Glass

BK7 is a borosilicate crown glass widely favored for its perfect balance of optical clarity, cost-effectiveness, and ease of polishing. It offers high transmission in the visible spectrum and relatively low dispersion, which minimizes chromatic aberrations in refractive telescope systems. While its thermal expansion is higher than fused silica, BK7 remains stable enough for many mid-range instrument applications where budget and machining flexibility are important. BK7 lenses are often used in eyepieces, field flatteners, and corrector plates, delivering sharp contrast and color fidelity.

Zerodur: Ultra-Low Expansion Glass-Ceramic

For the most demanding optical applications, Zerodur represents a benchmark material. This glass-ceramic composite exhibits near-zero thermal expansion, allowing telescope mirrors and substrates to maintain their figure with extreme precision across wide temperature ranges. Zerodur is employed in large professional observatories, space telescopes, and custom high-end amateur instruments where thermal distortion would catastrophically degrade image resolution. Its exceptional stiffness and homogeneity ensure minimal wavefront error, enabling consistent diffraction-limited performance essential for long-exposure astrophotography and adaptive optics systems.

When designing your telescope optics, the choice between fused silica, BK7, and Zerodur depends on your priorities—whether they be cost, thermal stability, ease of manufacturing, or ultimate precision. Understanding these materials’ unique optical and physical properties equips you to make informed decisions that directly impact your telescope’s clarity, reliability, and imaging prowess under real-world observing conditions.

Image courtesy of Pixabay

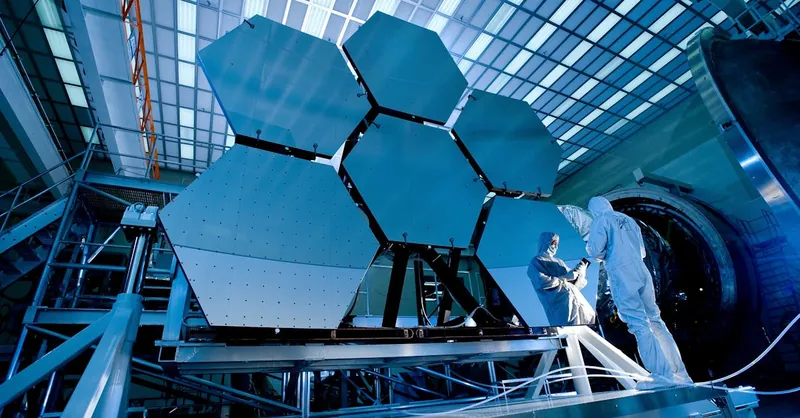

Structural Frame Materials: Comparing Aluminum Alloys, Carbon Fiber Composites, and Titanium for Telescope Tubes and Mounts

Selecting the right structural frame materials is pivotal for optimizing a telescope’s overall performance, stability, and usability. The frame—comprising the telescope tube and mounting system—must combine maximum rigidity, minimal weight, and thermal stability to maintain precise optical alignment and minimize vibrations during observation or astrophotography sessions. Three standout materials dominate advanced telescope frame construction: aluminum alloys, carbon fiber composites, and titanium. Each offers unique advantages and trade-offs that directly influence your build’s durability, portability, and precision.

Aluminum Alloys: Versatile and Cost-Effective

Aluminum alloys remain a perennial favorite for telescope frames due to their excellent strength-to-weight ratio, wide availability, and ease of machining or extruding into complex shapes. In particular, 6061 and 7075 series aluminum alloys are prized for their stiffness, corrosion resistance, and affordability. Aluminum’s moderate thermal expansion does require thoughtful design considerations, such as incorporating thermal breaks or flexible mounting points, to avoid focus shifts during temperature changes. Its relatively low density facilitates transportable telescope tubes and mounts, making aluminum ideal for mid-range amateur builds and some high-performance instruments where budget and fabrication flexibility are key.

Carbon Fiber Composites: Lightweight Rigidity and Thermal Stability

For astrophotographers and enthusiasts prioritizing ultra-lightweight yet supremely rigid frames, carbon fiber composites have revolutionized telescope structural design. Carbon fiber’s extraordinary stiffness-to-weight ratio far surpasses most metals, significantly reducing tube sag and mount vibration even in large-diameter telescopes or long focal length setups. Moreover, carbon fiber exhibits a very low coefficient of thermal expansion (CTE), enhancing thermal stability crucial for night-to-night repeatability and fine focusing. Its resistance to corrosion and environmental degradation further extends durability. However, carbon fiber’s higher material and fabrication costs, coupled with challenges in machining and joining, often place it in premium or custom-built telescope categories.

Titanium: Strength and Stability with Premium Resilience

Titanium alloys offer a compelling middle ground between metals and composites, combining exceptional strength, corrosion resistance, and moderate weight with notably low thermal expansion characteristics. Though heavier and more expensive than aluminum, titanium’s mechanical robustness and superior fatigue resistance enable highly stable mounts and tubes capable of enduring harsh environmental conditions without warping or deformation. Its resilience makes titanium an attractive choice for professional-grade telescopes and long-term installations exposed to humidity or extreme weather. The challenge remains in its machining complexity and higher cost, which typically reserves titanium for bespoke high-performance telescope frames where longevity and ultimate precision outweigh budget constraints.

Quick Comparison Table

| Material | Rigidity | Thermal Stability | Weight | Durability | Cost | Typical Use Cases |

|---|---|---|---|---|---|---|

| Aluminum Alloys | High | Moderate (higher CTE) | Low | Good (with treatment) | Low to Moderate | Amateur-mid range portable telescopes |

| Carbon Fiber | Very High | Very Low | Very Low | Excellent | High | Premium astrophotography rigs and large apertures |

| Titanium | High | Low | Moderate | Excellent | Very High | Professional, harsh environment telescopes |

Choosing among aluminum, carbon fiber, and titanium depends on your specific project goals, budget, and observing environment. Aluminum remains the versatile, budget-friendly choice with proven performance, while carbon fiber is unparalleled for lightweight structural rigidity and thermal stability. Titanium stands out when durability and long-term stability in challenging conditions are paramount. Understanding these materials’ comparative strengths ensures your telescope’s structural frame complements the advanced optics and engineering within your build, setting the foundation for superior celestial exploration.

Image courtesy of Susanne Jutzeler, suju-foto

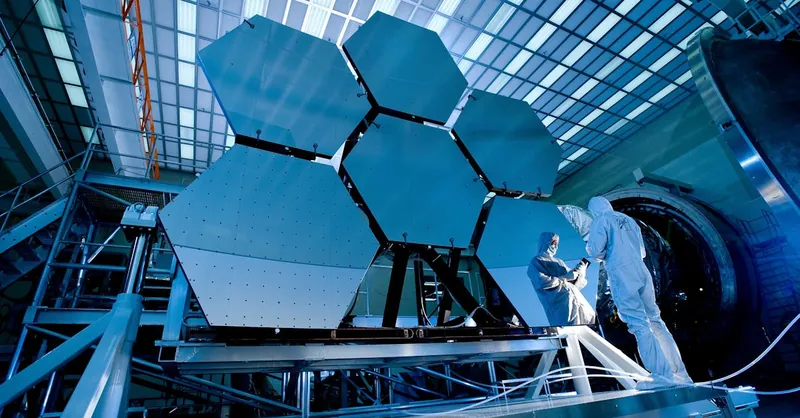

Mirror Substrates and Coatings: Enhancing Reflectivity and Reducing Aberrations

Selecting the optimal mirror substrate material and applying state-of-the-art reflective coatings are decisive factors in telescope performance, directly influencing image brightness, contrast, and optical fidelity. The substrate forms the physical base of the mirror, dictating how accurately the optical figure can be shaped and maintained under varying temperature and mechanical stresses. Meanwhile, the reflective coating defines the mirror’s reflectivity spectrum, durability, and susceptibility to environmental degradation, ultimately impacting the telescope’s sensitivity and longevity.

Advanced Mirror Substrate Materials

Choosing the right substrate material balances factors such as thermal expansion, structural rigidity, ease of polishing, and cost. The most advanced telescope mirrors employ substrates with ultra-low coefficients of thermal expansion (CTE) to mitigate image distortion caused by temperature fluctuations. Common leading options include:

- Zerodur

- A glass-ceramic material known for near-zero thermal expansion, ideal for maintaining a stable mirror figure during night-time temperature swings.

-

Its exceptional homogeneity and stiffness support producing mirrors with minimal surface errors and wavefront distortions, critical for high-resolution imaging and adaptive optics.

-

Fused Silica

- Praised for its low thermal expansion and excellent optical clarity across a broad range of wavelengths.

-

Fused silica substrates exhibit high resistance to thermal shock, making them ideal for fast-cooling mirrors in observatories and portable telescopes.

-

Pyrex (Borosilicate Glass)

- A more economical option with relatively low thermal expansion and good mechanical strength.

-

Often used in mid-range custom and commercial telescopes where cost-effectiveness is important, though it does not match Zerodur or fused silica in thermal stability.

-

Silicon Carbide (SiC)

- Emerging as a superior substrate in some advanced designs due to its extreme stiffness, high thermal conductivity, and low weight.

- SiC substrates cool quickly and resist deformation, allowing for lightweight segmented mirrors in large-aperture telescopes, including space-based instruments.

Cutting-Edge Reflective Coatings for Maximum Performance

The mirror coating dramatically affects the telescope’s reflectivity, durability, and resistance to scratching or oxidation. Modern advancements focus on maximizing reflectivity across the visible and near-infrared spectrum while maintaining coating longevity under outdoor conditions:

- Aluminum Coatings

- The traditional choice, aluminum offers broad-spectrum reflectivity (~88-92%) and ease of application via vacuum deposition.

-

Protective overcoats such as silicon dioxide (SiO₂) or magnesium fluoride (MgF₂) extend the coating life by preventing oxidation and scratching.

-

Enhanced Silver Coatings

- Silver provides superior reflectivity (~95%) in the visible and near-infrared range but is prone to tarnishing without robust protective layers.

-

Advanced multi-layer dielectric overcoats now enable silver mirrors to retain their high reflectivity for significantly longer durations, ideal for professional observatories and high-end amateur telescopes.

-

Dielectric Coatings

- Utilized primarily in narrow-band or specialized applications, dielectric multilayer coatings offer near 99% reflectivity within specific wavelength ranges.

- They also enable customized spectral reflectance profiles, reducing unwanted reflection losses and improving contrast by minimizing scattered light and ghost images.

Key Takeaways for Telescope Builders

- Prioritize substrates with ultra-low thermal expansion like Zerodur and fused silica to minimize mirror distortion and maintain precise optical figures throughout temperature variations.

- Evaluate cost versus performance: while Pyrex and borosilicate glasses offer affordable alternatives, superior thermal stability substrates yield noticeably sharper images and less frequent realignment.

- Invest in high-quality reflective coatings with durable protective layers to maximize mirror lifetime and maintain peak reflectivity, especially when exposed to moisture, dust, or temperature extremes.

- Consider innovative materials like silicon carbide for large or lightweight segmented mirrors designed for high-precision or space instrumentation.

Incorporating advanced mirror substrates with cutting-edge reflective coatings not only enhances your telescope’s optical efficiency but also ensures consistent, aberration-free imagery—empowering your astronomy pursuits from deep-sky observation to high-resolution astrophotography.

Image courtesy of Pixabay

Thermal Management in Materials: How Material Choices Affect Thermal Expansion, Distortion, and Image Clarity During Observations

Effective thermal management is crucial in advanced telescope construction, as temperature fluctuations can cause materials to expand or contract, leading to optical misalignments, image distortion, and loss of focus. The coefficient of thermal expansion (CTE) is a key property when selecting materials for both optical components and the structural framework. Even minute dimensional changes in mirrors, lenses, or support structures can degrade image clarity by introducing aberrations or shifting focal points during observing sessions.

Impact of Thermal Expansion on Telescope Performance

-

Optical Distortion and Focus Drift

Materials with high CTE experience measurable size changes as ambient temperatures drop overnight or heat up during daytime storage. This can cause the telescope’s mirror shape to deform or the optical path length to vary, resulting in blurred or inconsistent images. Precise instruments designed for astrophotography or detailed planetary observation are particularly sensitive to these effects, where maintaining a stable wavefront is paramount. -

Structural Misalignment

Thermal mismatch between different materials used in the telescope’s tube, mount, and optics can induce stress or warping. For example, combining aluminum (moderate CTE) with fused silica (very low CTE) without proper design considerations may cause relative shifts in component positioning as temperatures fluctuate. Such misalignment not only compromises image quality but also increases the frequency of recalibration and maintenance.

Material Strategies for Superior Thermal Stability

To combat thermal-induced problems, selecting materials with inherently low thermal expansion and designing thermally compatible assemblies are essential. Common approaches include:

- Using ultra-low expansion substrates like Zerodur and fused silica for mirrors and lenses ensures minimal figure distortion during thermal cycling.

- Employing frame materials such as carbon fiber composites and Invar alloys that exhibit very low CTE keeps support structures dimensionally stable, preventing optical axis shifts.

- Designing mechanical interfaces with flexible mounts or thermal breaks accommodates minor expansion differences without stressing optical elements or causing alignment drifts.

- Considering materials with high thermal conductivity, like silicon carbide, promotes rapid temperature equalization across components, reducing localized thermal gradients that could warp optics.

Optimizing Image Clarity Through Thermal Compatibility

Successful thermal management integrates both material selection and engineering design to maintain optical alignment and image fidelity throughout variable observing conditions. Materials chosen for their minimal thermal expansion and matched CTE reduce focus shifts and aberrations, critical for long-exposure astrophotography and high-resolution observing sessions. By prioritizing thermal stability in materials, telescope builders can achieve consistent, distortion-free images, maximizing performance regardless of environmental challenges.

Image courtesy of Pixabay

Material Innovations in Vibration Damping and Stability: Incorporating Viscoelastic Polymers and Honeycomb Structures for Vibration Reduction

Achieving exceptional vibration damping and structural stability is a fundamental challenge in advanced telescope building, directly impacting image sharpness and long-exposure astrophotography quality. Even minute vibrations—from wind gusts, motor drives, or mechanical resonances—can blur images, degrade resolution, and increase tracking errors. Recent material innovations incorporating viscoelastic polymers and honeycomb core structures revolutionize vibration control by combining lightweight design with superior damping properties, making them indispensable in high-performance telescope construction.

Viscoelastic Polymers for Enhanced Damping

Viscoelastic polymers possess unique energy-absorbing characteristics that convert vibrational energy into heat, drastically reducing oscillations within structural components. When integrated as damping layers or bonding media within telescope tubes and mounts, these materials effectively suppress resonance frequencies that typically compromise optical alignment. Benefits include:

- Reduced Micro-vibrations that blur high-magnification viewing and astrophotography, especially important for long focal length or high-resolution instruments.

- Improved Mechanical Stability enabling more precise motor tracking and smoother operation of equatorial or alt-azimuth mounts.

- Adaptability—viscoelastic materials can be engineered with tailored stiffness and damping coefficients, allowing custom tuning for specific telescope designs.

Honeycomb Core Structures for Stiffness and Lightweight Support

Honeycomb sandwich panels, typically constructed with thin face sheets bonded over a lightweight honeycomb lattice (aluminum, Nomex, or carbon fiber), provide remarkable stiffness-to-weight ratios and inherent vibration damping. Their geometric architecture efficiently distributes mechanical loads while minimizing flexure and resonance. Key advantages include:

- High Rigidity with Low Mass, crucial for maintaining optical alignment without weighing down mounts or requiring oversize drive systems.

- Intrinsic Energy Dissipation characteristic from the micro-cellular structure reduces vibration transmission throughout the telescope framework.

- Thermal Stability as certain honeycomb cores withstand temperature changes without significant deformation, synergizing well with low-CTE materials in optics and frames.

Integrating Viscoelastic Polymers and Honeycomb Structures in Telescope Design

Modern telescope builders increasingly adopt composite sandwich structures combining rigid carbon fiber face sheets, viscoelastic damping layers, and honeycomb cores to suppress unwanted vibrations effectively. This layered construction provides:

- Superior vibration attenuation compared to monolithic metal or composite tubes, enhancing image stability during exposure and tracking.

- Lightweight yet robust frames that do not compromise portability or load capacities of mounts and drives.

- Customizability in tailoring damping frequencies and stiffness by varying polymer formulations and honeycomb cell sizes.

By leveraging these advanced materials and structural strategies, astronomers and telescope engineers can dramatically improve vibration resistance and overall stability, ensuring crisp, clear celestial images free from distortion caused by mechanical oscillations. These innovations represent a significant leap forward in telescope material science, marrying mechanical engineering with astronomical precision to maximize observational capabilities.

Image courtesy of Pixabay

Protective and Environmental Considerations: Weather Resistance, Corrosion Protection, and Dust Control in Telescope Materials

When building an advanced telescope, the choice of materials extends beyond optical precision and structural integrity—environmental resilience is equally critical for ensuring reliable performance and longevity. Telescopes are often exposed to harsh outdoor conditions including humidity, temperature fluctuations, dust, and UV radiation, all of which can degrade materials, promote corrosion, or contaminate optical surfaces. Integrating weather-resistant materials, effective corrosion protection, and dust control strategies into your telescope build safeguards sensitive components, reduces maintenance, and preserves image quality over time.

Weather Resistance and Corrosion Protection

-

Material Selection for Environmental Durability

Metals such as stainless steel, anodized aluminum, and titanium alloys excel in resisting rust and corrosion caused by moisture and atmospheric contaminants. Carbon fiber composites also offer excellent resistance to environmental degradation and UV exposure, maintaining mechanical strength and dimensional stability without surface oxidation. Careful use of sealants and surface treatments further enhances longevity by preventing moisture ingress and chemical attack. -

Protective Coatings and Finishes

Applying anodizing on aluminum parts not only improves corrosion resistance but also provides a harder, wear-resistant surface that withstands abrasion and UV damage. For steel elements, powder coating or electroplating with protective metals like zinc or nickel extends service life in humid or salty environments. In optical assemblies, hydrophobic and anti-reflective coatings protect lenses and mirrors from moisture, dust adhesion, and surface degradation without compromising optical throughput.

Dust Control Measures in Telescope Construction

Dust accumulation on optical surfaces or mechanical parts severely impacts image contrast and precision movement. Advanced telescope builds employ multiple strategies to minimize dust intrusion:

- Sealed optical housings and tube assemblies use carefully designed gaskets and labyrinth seals to block airborne particulates while allowing necessary ventilation.

- Dust-resistant filter membranes or screens can be incorporated at openings to maintain airflow but exclude fine particles.

- Use of cleanroom-grade assembly procedures and storage in dust-controlled environments during construction and maintenance further prevents contamination.

- Regular use of non-abrasive cleaning tools and protective lens caps safeguards optical components against dust abrasion and scratches.

Implementing these protective and environmental considerations at the material selection and design stages results in a telescope that withstands diverse climatic conditions and remains optically pristine. By prioritizing weather resistance, corrosion protection, and effective dust control, you ensure your advanced telescope maintains peak performance for years of astronomical exploration and astrophotography excellence.

Image courtesy of Andre

Material Selection for Portable vs. Fixed Telescopes: Trade-offs in Weight, Strength, and Cost

When building telescopes, whether transportable models for field use or permanent observatory-class instruments, the choice of materials must strike a careful balance among weight, strength, and cost—each factor critically influencing the telescope’s functionality and user experience.

Portable Telescopes: Prioritizing Lightweight and Durability

For portable telescopes designed for easy transport and quick setup, lightweight materials like carbon fiber composites and high-grade aluminum alloys are favored for frames and tubes. Their high strength-to-weight ratios reduce bulk and enable manageable handling without compromising rigidity. This is vital for astrophotographers and amateur astronomers who require mobility to chase clear skies or deploy telescopes on travel trips. Additionally, materials in portable builds should offer:

- Corrosion resistance to withstand outdoor environmental exposure during transit.

- Thermal stability sufficient to maintain optical alignment in variable observing conditions.

- A balanced cost point, as portable telescopes often target enthusiasts with budget constraints.

However, ultra-lightweight materials such as carbon fiber come with higher price tags and manufacturing complexity, placing them at the premium end of portable telescope builds.

Fixed, Observatory-Level Telescopes: Emphasizing Strength and Stability

Conversely, fixed telescopes destined for observatory domes or permanent installations can afford to prioritize maximum structural strength and thermal inertia over weight. Materials like titanium alloys, Zerodur glass-ceramics for mirrors, and stainless steel frames provide exceptional rigidity and resistance to environmental and mechanical stress, crucial for long-term optical precision and minimizing alignment shifts in large-aperture instruments. Cost constraints are typically secondary in professional deployments focused on ultimate performance.

Key considerations for fixed telescopes include:

- Enhanced vibration resistance using robust materials and damping strategies to allow stable tracking over extended observations.

- Superior thermal mass and expansion characteristics to reduce image distortion caused by temperature changes.

- Materials chosen for longevity and low maintenance in harsh environments, accepting heavier assemblies that rarely move.

Balancing Trade-offs: Choosing Materials by Application

Understanding the key trade-offs helps telescope builders define material choices aligned to their telescope’s intended purpose:

| Telescope Type | Primary Priorities | Common Material Choices | Cost Implications |

|---|---|---|---|

| Portable Telescopes | Low weight, corrosion resistance, moderate cost | Carbon fiber composites, aluminum alloys | Moderate to High |

| Fixed Telescopes | Structural strength, thermal stability, longevity | Titanium alloys, stainless steel, Zerodur | High to Very High |

Making informed material selections based on these factors ensures that your telescope’s structure supports optimal optical performance, meets usability requirements, and fits your budgetary goals—whether you need a lightweight instrument for travel or a heavyweight observatory mainstay designed for decades of celestial study.

Image courtesy of Jan van der Wolf

Integration with Astrophotography Equipment: Materials Optimizing Compatibility with Cameras, Filters, and Adaptive Optics Systems

For amateur and professional astronomers alike, building a telescope that seamlessly integrates with advanced astrophotography equipment is essential to maximize imaging quality and operational efficiency. Selecting materials that optimize compatibility with digital cameras, filter wheels, and adaptive optics (AO) systems enhances the overall performance by minimizing mechanical flexure, thermal shifts, and electromagnetic interference—all critical factors in capturing sharp, high-contrast celestial images.

Material Considerations for Camera and Filter Compatibility

-

Low Thermal Expansion Materials

Astrophotography demands precise, repeatable alignment between the telescope optics and imaging sensors. Materials such as carbon fiber composites, Invar alloys, and aluminum with thermal breaks minimize dimensional changes that cause sensor misalignment or focus drift during temperature fluctuations. This stability ensures filters and cameras remain securely positioned relative to the optical axis, reducing the need for frequent recalibration. -

Electromagnetic Compatibility and Grounding

Certain electronic astrophotography devices, including cooled CCD/CMOS cameras and motorized filter wheels, are sensitive to electromagnetic interference (EMI). Employing conductive materials, such as aluminum or titanium alloy mounts, along with proper grounding, shields electronics and reduces noise in captured images, improving signal-to-noise ratios and overall image fidelity. -

Precision Machining and Mounting Interfaces

Materials that permit high-precision machining and consistent thread tolerances—like aluminum alloys and titanium—allow for stable and repeatable attachment points for cameras, off-axis guiders, and filter wheels. This precise fitment eliminates mechanical backlash or slippage, which can degrade image sharpness during long exposures.

Enhancing Adaptive Optics Integration Through Material Choice

Adaptive optics systems rely on rapid adjustments of deformable mirrors or wavefront sensors to correct atmospheric distortions in real time. Incorporating materials that complement these sensitive components improves AO performance:

- Vibration Damping: Materials such as viscoelastic polymers and carbon fiber laminates reduce micro-vibrations transmitted through the telescope structure, critical for allowing AO systems to operate without interference from mechanical jitter.

- Thermal Stability: AO units are highly sensitive to heat-induced misalignment. Using low CTE materials for AO interfaces helps maintain optical path integrity during night-long imaging sequences.

- Lightweight Structural Components: Reducing overall system mass with advanced composites facilitates faster and more precise AO motor movements, enabling higher correction speeds and improved image clarity.

By prioritizing these material attributes, telescope builders can ensure seamless integration with astrophotography gear, resulting in enhanced image quality, reduced maintenance, and greater operational reliability. Whether outfitting your telescope for deep-sky imaging, planetary photography, or scientific research, focusing on materials that support rigid, thermally stable, and electromagnetically compatible mounts and interfaces empowers your astrophotography endeavors with professional-grade precision and consistency.

Image courtesy of Tima Miroshnichenko

Sourcing and Cost Considerations: Where to Find Advanced Telescope Materials and How to Balance Budget with Performance Needs

Securing high-quality advanced telescope materials requires strategic sourcing combined with a clear understanding of budget constraints and performance goals. Many premium materials—such as carbon fiber composites, Zerodur glass-ceramics, and titanium alloys—are specialty products that may not be widely available through general hardware suppliers. Instead, sourcing often involves engaging with specialized vendors, industrial suppliers, or astronomical instrument manufacturers who cater to precision optics, aerospace composites, and custom metal fabrication. Building a relationship with reputable suppliers ensures access to accurate material specifications, certifications, and technical support critical for high-performance telescope construction.

Balancing cost and material performance is a pivotal challenge. Here are key considerations to optimize your investment:

-

Prioritize material properties most critical to your telescope’s design—thermal stability, rigidity, or weight—then allocate budget accordingly. For example, investing in a low-CTE mirror substrate like Zerodur can significantly enhance image quality, while selecting a more affordable aluminum alloy for structural components may reduce cost without compromising key functions.

-

Leverage surplus and industrial-grade materials from aerospace or optics industries where possible. Surplus carbon fiber sheets or off-cut optical glass blanks can offer cost savings when sourced from trusted liquidation or secondary markets, provided material quality is certified.

-

Consider modular design approaches that allow the incremental upgrade of components. Starting with cost-effective materials for structural frames and upgrading to premium mirror substrates or advanced coatings later can spread expenses without sacrificing early project progress.

-

Factor in machining and processing costs, which can sometimes exceed raw material expenses—especially with exotic materials like titanium or silicon carbide. Collaborate with fabricators experienced in handling these materials to avoid costly mistakes and rework.

-

Explore community resources and partnerships, such as amateur astronomy clubs or university labs, for group purchases or shared access to specialized materials and fabrication facilities, improving affordability and technical guidance.

By thoughtfully sourcing materials aligned with your telescope’s technical demands and budget framework, you can construct instruments that deliver professional-grade performance without unnecessary expenditure. Strategic procurement and cost management empower both amateur builders and advanced hobbyists to push the boundaries of astronomical observation, turning material innovations into stellar viewing experiences.

Image courtesy of Tima Miroshnichenko